Manufacturing

Your time, safety, and satisfaction are important to us!

From the moment we melt our pure aluminum ingots to the time we package and ship, our products have gone through over a dozen physical check points before making them to your site. Our on-site technicians and engineers check the quality of each and every batch of aluminum during its manufacturing process to ensure consistency from batch to batch.

At Matrixtion, we manufacture all our parts and components for all our systems. What makes us the leader and most trusted brand is that we have 100% complete control over the entire process. From aluminum and powder coating to packaging and distribution, Matrixtion is the safest and strong Ceiling Tiles, Facade,Lader Cut system on the market.

Melt Workshop

Our process starts with 100% pure aluminum ingots, that we melt, extrude and cast into the many components that make our many brands. We have many processes in place to ensure we meet the highest safety and quality standards in the design, manufacturing, packaging of our products.

We believe in being “hands-on” throughout our process, true Artisans in the aluminum industry

Extrusion Workshop

After Melted the aluminum ingot, The next step put the aluminum bar in the extrusion machine then the accuracy of size is ensured by precision extraction through the mold.

Widely used in extruding profiles, curtain wall ,doors and Windows, etc

Aluminum Rolls Workshop

The superior quality of our products is something we proudly stand behind. We have some of the top engineers working on-site with our production teams to deliver premium quality products for your home.

Powder Coating Workshop

Our Powder Coating process uses no VOC’s (Volatile Organic Compounds). The powder is baked into the aluminum, creating a strong durable finish that is virtually maintenance free and UV resistant.

Powder coat finish resists harsh weather, heat, scratches, cracking and peeling.

Salvagnini Workshop

In 2014, we purchased the fully automatic machines and set up high-level production lines from Italy Savanini Company, which made the production quantity and quality of our company develop rapidly. Our customers range from home decoration to commercial buildings to airports, subways, and so on the high-level area.

Bending Workshop

Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal.

Die Casting Workshop

4 sets aluminum alloy die casting machines from 200T to 1250T

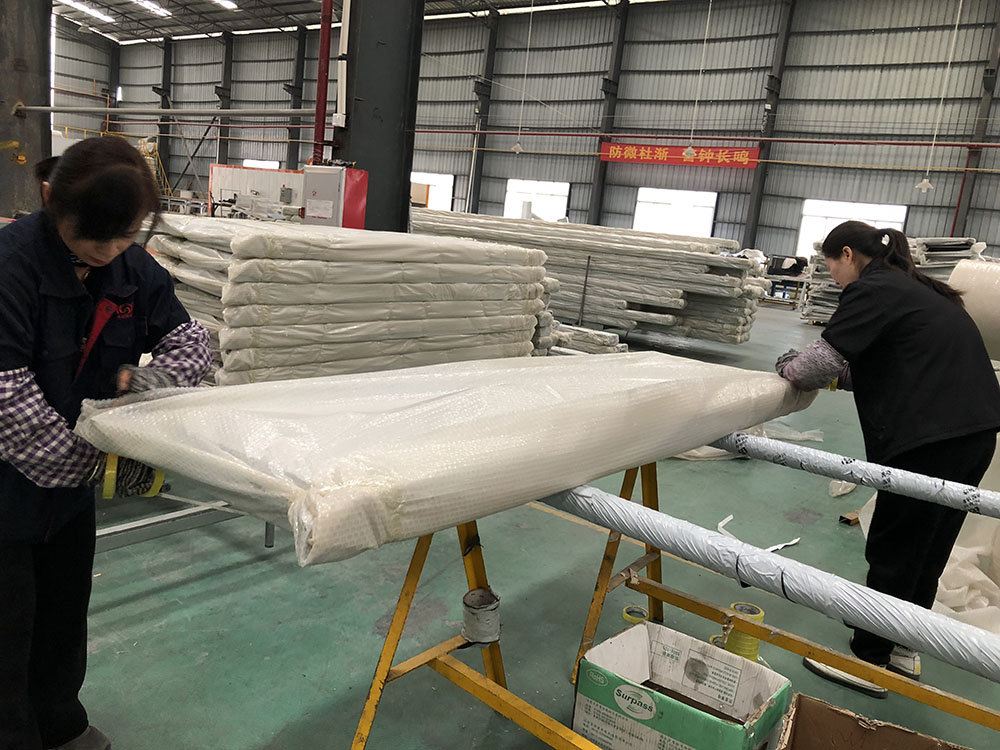

Package Workshop

Before the order is confirmed, we will provide the packing plan for the customer to choose.

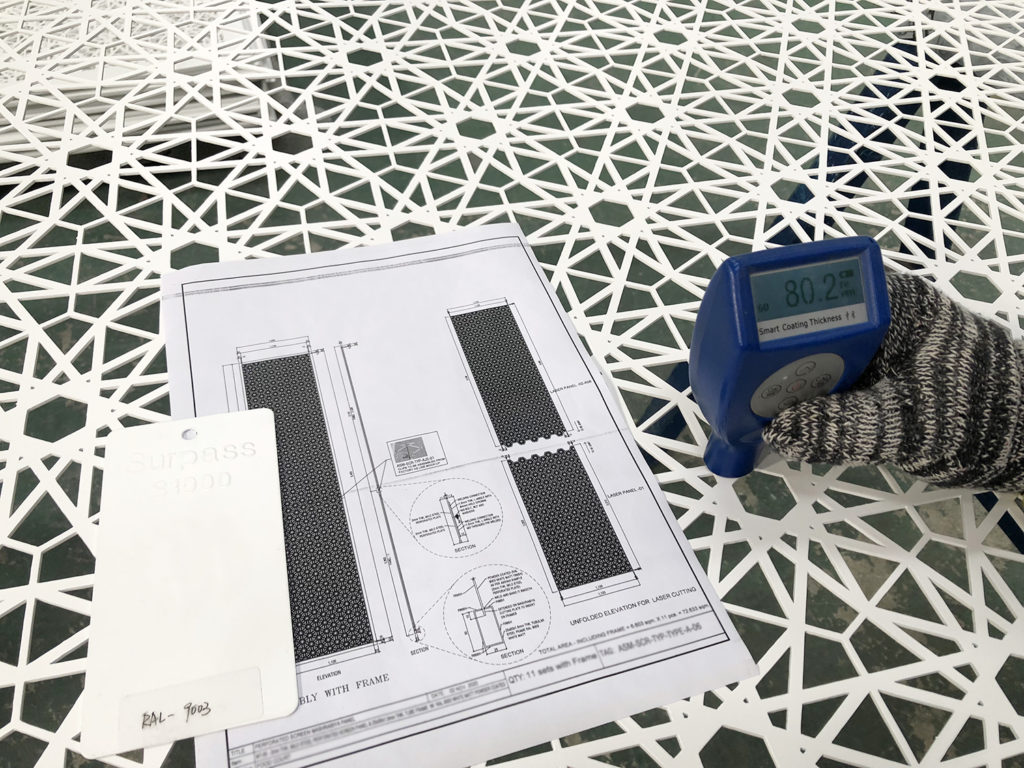

Quality Control

our products have gone through over a dozen physical checkpoints before making them to your site. Our on-site technicians and engineers check the quality of each and every batch of aluminum during its manufacturing process to ensure consistency from batch to batch.

Color,Sizes, Powder Coating Thickness, Surface, Corner and so on regular and special checkpoints

100% inspection before shipment.

As every project is different, we can manufacture to your specifications to ensure your unique design ideas come to life. Whether it’s steel, aluminum, we can fabricate it to fit your application.

Send us your architectural specifications, building plans, rough sketch, site plan or even a photo and we can tailor a solution for you.

ADDRESS

No.13 Chuangxin Da Dao East Industrial Park, Leping, Sanshui, Foshan, Guangdong, China

BUILD

Metal Ceiling

Wall Facade

Laser Cut Art

Baffle Ceiling

Pergola

Fence

Ac Covers

LEARN US MORE

About Us

Manufacturing

Customer Service

Photo Gallery

FAQ

Blog

Pattern Library

CONTACT US

Email:marketing@matrixtion.com

PH: 0086-13030200489